Permacron® Reducers 3364 – 3365 – 3366

Permacron® Reducers for Passenger Car Refinishing.

With these reducers, the application viscosity of the base materials can be adjusted to guarantee ideal application under all conditions.

Permacron® MS Dura plus 8580

Permacron® Reducer 3364

Permacron® Reducer 3380

Permacron® Reducer 3365 slow

Permacron® Reducer 3385 slow

Permacron® Reducer 3366 extra slow

Permacron® Reducer 3364.

Permacron® Reducer for Passenger Car Refinishing.

Universal reducer for all 2K acrylic products.

Adjusts the viscosity of priming materials and top coats at low and medium temperatures.

Permacron® Reducer 3365 slow.

Permacron® Reducer for Passenger Car Refinishing.

Reducer for all 2K acrylic products.

Improves levelling and absorption of overspray at spray booth temperatures of above +25°C and for large objects.

Permacron® Reducer 3366 extra slow.

Permacron® Reducer for Passenger Car Refinishing.

Reducer for all 2K acrylic products.

Improves leveling and absorption of overspray at spray booth temperatures of above +35°C and for large objects.

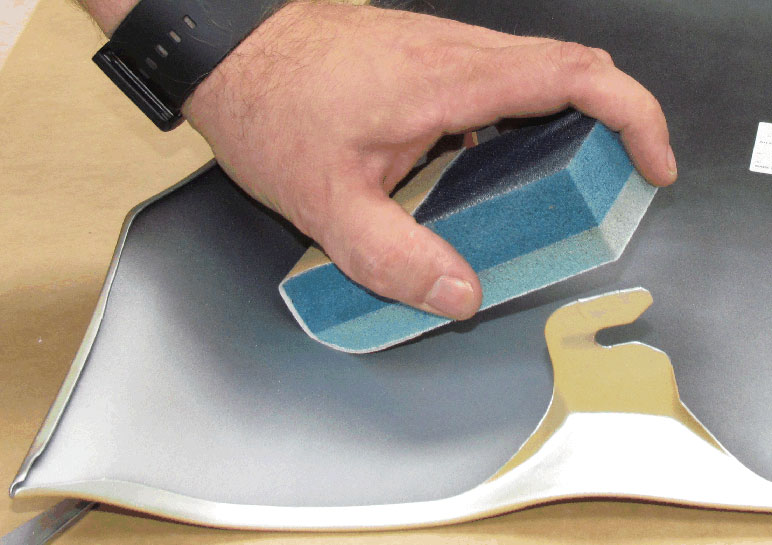

.jpg) Manual sanding

Manual sanding.jpg) Manual sanding with sanding block

Manual sanding with sanding block.jpg) Manual sanding for profiles

Manual sanding for profiles.jpg) random orbital sander

random orbital sander.jpg) Orbital sander

Orbital sander.jpg) Rolls

Rolls.jpg) Stationary disc sanding

Stationary disc sanding.jpg) Cross belt sanding

Cross belt sanding.jpg) Stroke belt sanding

Stroke belt sanding

.jpg) Delta sander

Delta sander